How to Select a Sewing Machine Needle

In yesterday’s post we talked about the Anatomy of a Sewing Machine Needle and how all those parts work together to create stitches. For the best sewing quality possible, you’ll want to use the right needle for the job. Let’s take a look at the types and sizes of needles available. There are hundreds of variations of sewing machine needles, so how do you choose from the myriad of options? Needles are selected according to the needle system required for the sewing machine, the type of needle for the fabric, and the needle size for the thread. Taking the selection process one step at a time is an easy way to determine which needle you need.

Step 1: Needle System

The needle system refers to which needles will fit in which sewing machines. This is determined by the shape of the needle shank. Check your owner’s manual to see which system your sewing machine needs. Home sewing machines use a flat shank, System 130 needle. Here is a chart of the needle systems required in our Sailrite sewing machines: If you own another machine, you might find your needle system in this PDF.

Step 2: Needle Type

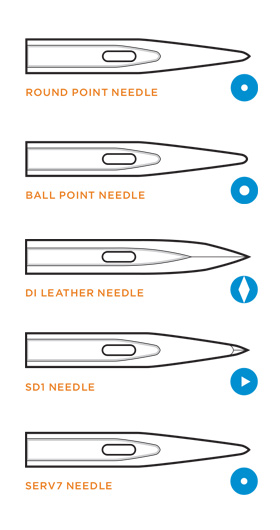

The Needle Type refers to the point and tip of the needle. This is where the fabric you are sewing comes into consideration. There are many variations on these needle types and you can find a specific needle for almost any application, but here is a basic overview of some common needle types.

Round Point (Sharp): This is the most common needle type and it features a sharp point that can be used for all general sewing.

Round Point (Sharp): This is the most common needle type and it features a sharp point that can be used for all general sewing.

Ball Point: Ball points are a specialty needle designed for sewing knit fabrics and stretchy materials. The blunt point preserves the elasticity of the fabric, because it passes between the fabric’s fibers rather than cutting through them.

DI Leather: This is a specialty needle designed for working with dry, heavy, or hard leather. The diamond shaped blade of the DI Leather Needle cuts the tough fibers so the needle doesn’t have to separate them.

SD1: This is another specialty needle designed for sewing fine leather goods such a gloves or clothing. It also works well for heavy sailcloth assemblies. The SD1 needle is similar to the DI Leather Needle but it has a smaller cutting point that cuts and pushes the fabric out of the way.

Serv7: This needle has an optimized scarf shape that makes it perfect for sewing through heavy fabrics. The Serv7 needle features a reinforced blade to help avoid skipped stitches and reduce needle breakage. This needle is recommended for use with Tenara threads.

Step 3: Needle Size

The size of a needle is determined by the diameter of its blade and is calculated by taking the diameter of the blade in millimeters times 100. For example, a needle with a .80 mm diameter is size 80. Needles sizes are either listed by the diameter (ex. size 80), the numerical “size” equivalent (ex. #12) or both. For context, a #12 (80) needle is small and a #22 (140) is a very large needle. The size of the needle you want should correlate with the fabric you are sewing. A thicker, heavier fabric will require a larger needle than a lightweight sheer. For a general reference, you can use this chart:

| Fabric | Needle Size | Thread Size |

|---|---|---|

| Lightweight | 10 – 12 | Home Threads / V-30 |

| Medium-weight | 14 – 16 | V-46 / V-69 / Upholstery Thread |

| Heavyweight | 18 – 20 | V-92 / PTFE Threads |

| Very Heavyweight | 21 – 23 | V-138 / Heavy PTFE Threads |

For more specific recommendations, you can use our Thread and Needle Recommendation Guide, which makes needle recommendations based on fabric choice, organized by brand. With your needles chosen, now all that’s left to do is notice when you need a new needle and install it in your sewing machine. Check back tomorrow for the third and final post in this series: How to Change a Sewing Machine Needle.

This post was updated May 21, 2014.

Pingback: Anatomy of a Sewing Machine Needle | Do-It-Yourself Advice Blog.

Pingback: How to Change a Sewing Machine Needle | Do-It-Yourself Advice Blog.

Reblogged this on The Sailing Vessels Dragon Wing and commented:

One more good article, this time on needle selection for sewing machines. I have a few projects in mind for this winter, and this may come in handy!

Do you have any “troubleshooting” hints on how to tell if you have the the wrong needle? For example, if the needle is too large, what problems might I see on my project? Puckering? Missed stitches? Same with too small/wrong tip, etc. Thanks!

Hi Sue,

Good question! I could do a whole separate post on this, but here’s a quick reference.

There are a few indicators that your needle size may be too large or too small for the fabric you’re sewing. Fabric puckering could indicate that the needle and thread are too large for the fabric, so you might want to try sizing down. Skipped stitches could be caused by either the needle being too big or too small (although, machine timing issues can also be the cause of skipped stitches). Tension issues are also common signs of a needle that is too big or too small. Visible knots on the under side of the fabric (even after more upper tension is applied) can be a sign of a needle being too small. Knots randomly on the top and bottom of your fabric can be a sign that the needle is too big.

Thanks, Nikki! That is exactly what I was looking for!

do different thread sizes require different needles? Is there a chart for this?

Hi Ginny,

Different size threads would require different size needles. It all relates to the weight of your fabric. Heavier fabric needs a bigger needle and thread, while lighter fabrics need smaller needles and lighter thread.

inny said:

May 19, 2015

10:02 am

do different thread sizes require different needles? Is there a chart for this?

I don’t think you answered this question very well. I would also like to see a chart for thread size/needles.

Sometimes I use very heavy thread, especially for the top stitch when doing automotive seats or real french seams. Also, I would like to see a comment about how the thread slides through the needle.

Hi Dave,

Sorry you found my previous response to be vague. In light of more requests for this information, I have edited the post to include a general chart comparing fabric weight to appropriate needle and thread sizes. How the thread slides through the needle is discussed more in the first post of this series, Anatomy of a Sewing Machine Needle (https://sailrite.wordpress.com/2013/08/22/anatomy-of-a-sewing-machine-needle/) in the section titled “how a stitch is made.” I hope that helps answer your questions!